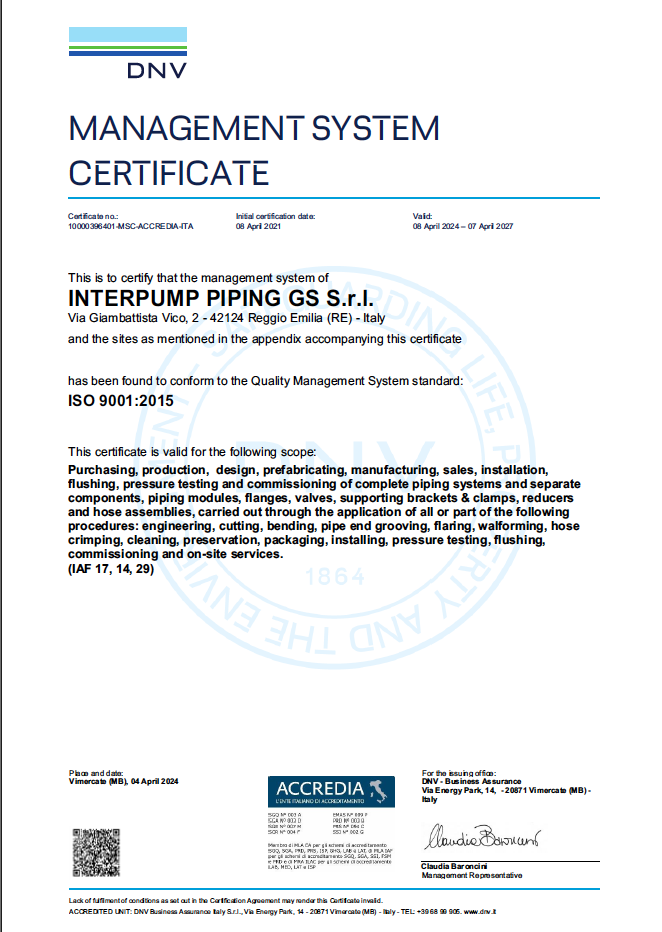

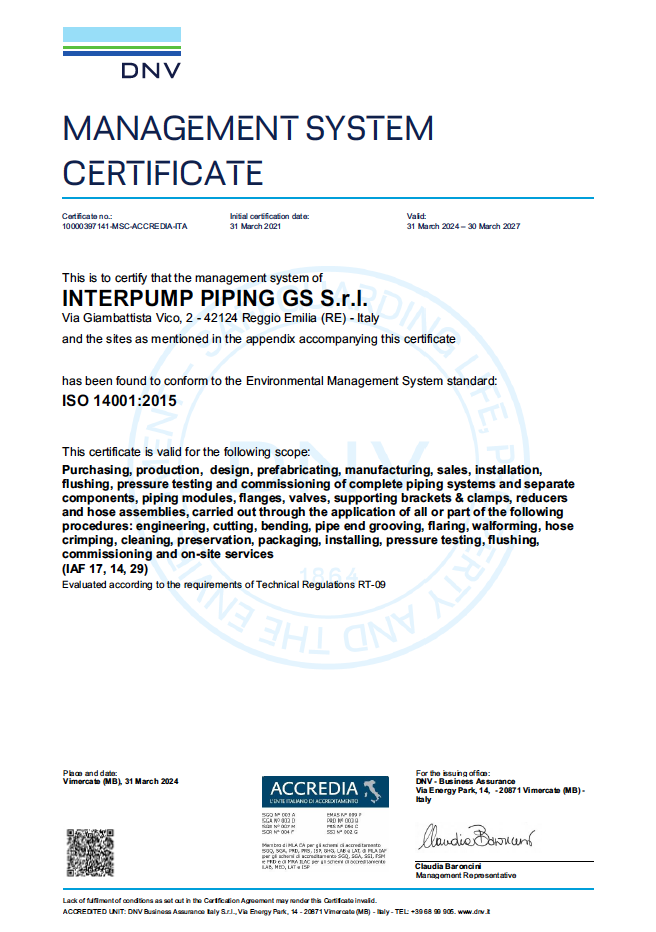

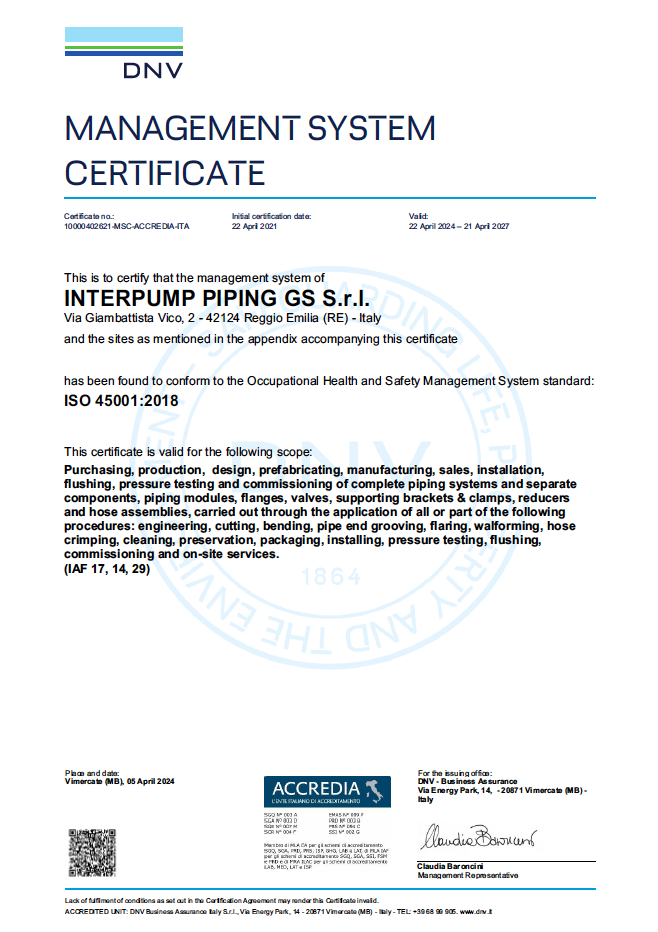

Quality

Ensuring the highest quality of products and services to our customers is always a priority. Through careful quality management of both in-house operations, as well as suppliers and subcontractors, GS-Hydro makes sure our products are in-line with the most restrictive standards.

Type Approvals

In order to satisfy client requirements across various segments and different applications,

GS-Hydro made sure to be approved by all renowned certification bodies.

GS-37° and GS-90° Flare Flange Systems as well as the GS-Retain Ring Systems are approved by the following classification societies:

DNV GL - DNV GL Group

LR -Lloyd's Register of EMEA

ABS - American Bureau of Shipping

BV - Bureau Veritas

RINA - Registro Italiano Navale

RMRS - Russian Maritime Register of Shipping

NKK - Nippon Kaiji Kyokai

CCS - China Classification Society

KR - Korean Register

You can download our type-approvals from the download-page.

The GS-Piping Connection Systems are also approved for use in offshore by NORSOK (piping specifications IS70, IS80, GS70 and JS80).

What is more, GS-Products that hold the type approvals are tested according to IACS (International Association of Classification Societies Ltd) requirements – combined vibration & pressure pulsation test and the fire endurance test.

Vibration & Pressure Test

GS-Products meet IACS (International Association of Classification Societies Ltd) test requirements.

IACS Combined Vibration & Pressure Pulsation Test

P 2.11.2.2.2/3

- In order to establish the capability of the mechanical joint assembly to withstand fatigue stress

- The specimen is to withstand a minimum of 10 million cycles of mechanical load

- The vibration test is carried out simultaneously with the pressure pulsation test, where impulse is to be raised from 0 to 1,5 times the design pressure

- The number of pressure peak cycles is minimum 500.000

Fire Endurance Test

GS-Products meet IACS (International Association of Classification Societies Ltd) test requirements.

IACS Fire Endurance Test

P 2.11.5.5.6

- In order to establish the capability of the mechanical joint assembly to withstand the effects of fire

- The specimen is subject to fire for 30 minutes at a temperature of 800°C, while water at the design pressure of the joint is circulated inside

- After the testing, the specimen is subject to a hydrostatic tightness test